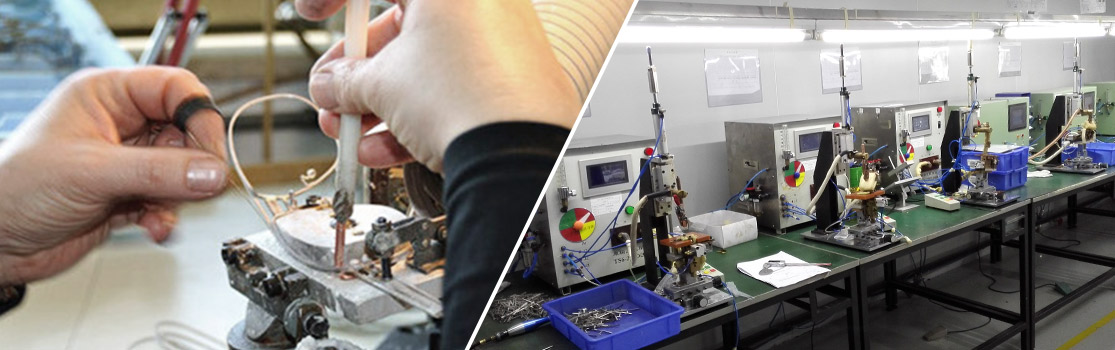

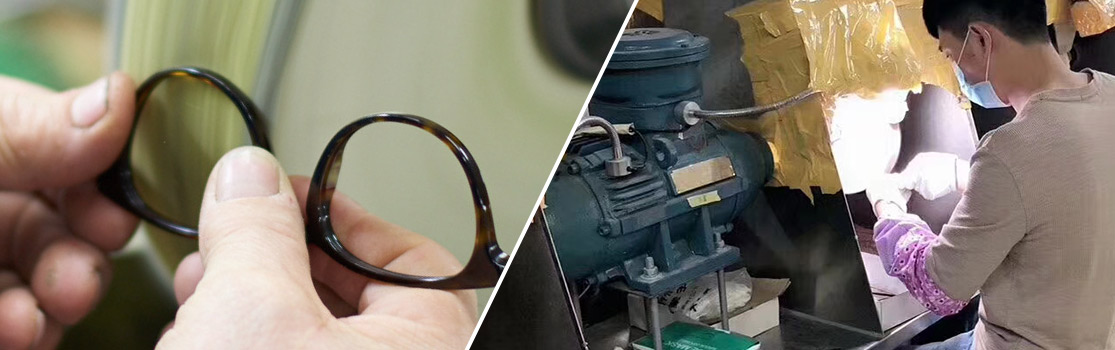

Providing reliable and high quality of service to customers are the core business values of Comarc. We have a professional product Engineering team and QC team who are working according to customer's serious standard to guarantee the quality of our products. To ensure the quality of our products stable and reliable, we monitor every process of the production from basic materials to finished products by product Engineering team and QC team.

We build and maintain strategic alliance with both vendors and clients to enhance the added value to clients.

In addition to improvement of production technology, we seek for innovation and breakthrough on management and marketing expansion.