HD acetate is also a kind of acetate material, in the design and mass production, HD also has its limitations like other acetate materials.

HD encourages breaking through the following limitations, but it is recommended not to make splatters directly to customers; In order to avoid the customer selected, but not delivered. Instead, it takes the practice of "research and development" first, and then recommends it to customers when it can be made on bulk production.

1.This guideline is formulated in view of the problem that HD-BMT sheet is prone to "dirt"/" water stripe "/" color stripe "on the surface of BMT during production.

Design:

1.1) It is recommended that all BMT designs should be in the middle of the spleen and not in the edge position. The BMT pattern should be at least 1.5mm away from the edge

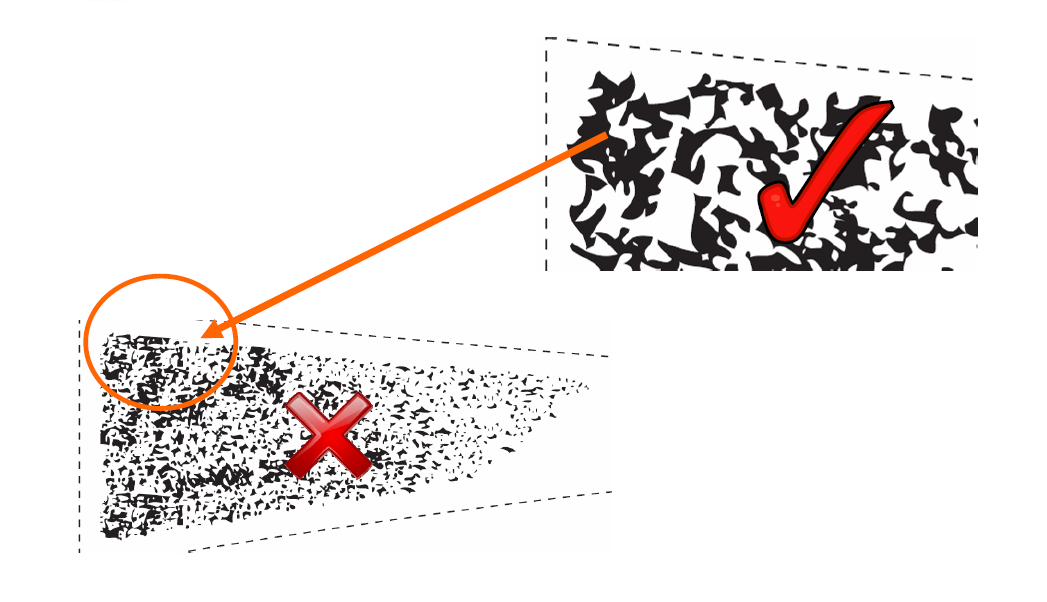

1.2) It is recommended that BMT should not use large plane area

(The plane area of BMT at any position shall not be greater than 1.5mm*1.5mm)

Otherwise, it is very easy to have problems such as "rainbow pattern"

1.3) Due to positioning, please do not design BMT in the head and tail of the temple at the same time, it is recommended to use Foil Logo for the tail of the temple.

1.4) It is recommended that BMT not be designed on monochrome pearlescent material.

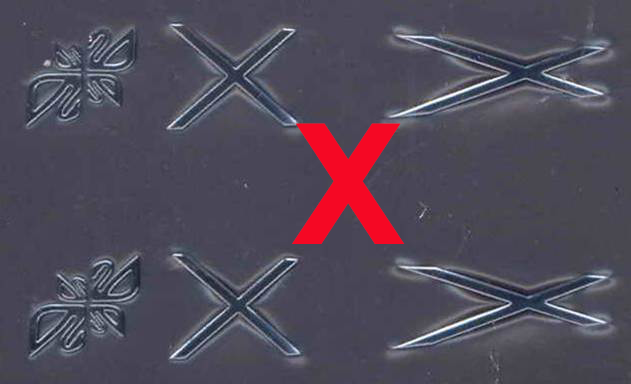

False case 5: BMT is designed on the pearlescent material, so that the pearlescent material has deep marks, which is unacceptable.

2. Cutting material: can not heat cutting material, need to use CNC carved temple shape.

3. Wire-core Shooting:

It is to reduce the temperature of the baking material when shooting wire-core as much as possible. The parameters for reference are as follows. Please adjust them according to the conditions of each factory:

- Use high frequency machines whenever possible;

- If using ordinary oven, the temperature must be controlled.

4. BMT small point is disconnected, should be connected:

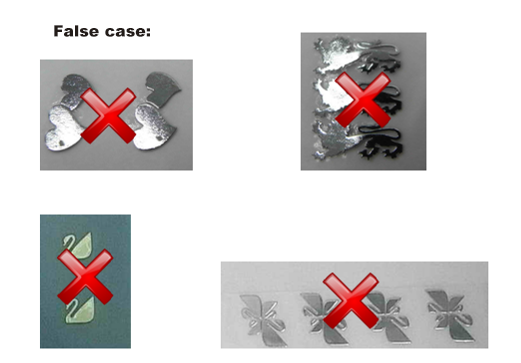

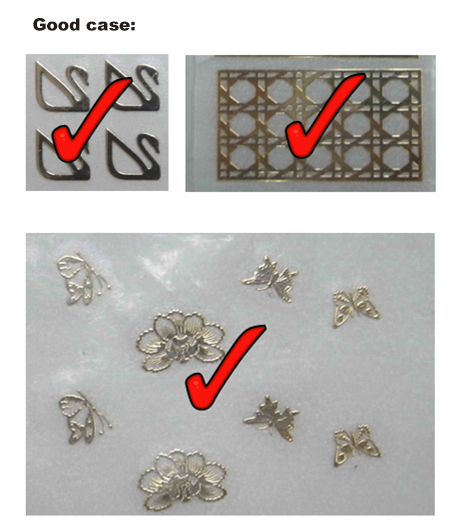

Case (BMT points are too small and easy to drop) :

Case (Mass production is feasible) :

5.Choice of CNC cutting and punching

1). All BMT and TG are matched with CNC cutting.

2). There are clear requirements for pattern positioning, and the accuracy is controlled within the range of +/-0.5mm

Otherwise, there is an error in punching. For the whole batch of goods, the tolerance will be greater than +/-1.0mm, and control instability.

3). The temple with BMT on the whole temple will be subject to the head of the temple, and the BMT of the tail of the temple will be relative to the tail of the temple.

The distance may have an error of 2~3mm.

Picture: The position distance between BMT and temple head is inconsistent (CNC cutting will be based on temple head)

HD TG

In view of the problem that HD-TG acetate material is easy to burst at the TG position during production,

1. Design:

All TG design needs to be the same as BMT. The TG pattern should be in the middle of the temple, not in the edge position.

The TG pattern should be at least 1.5mm away from the edge. Such as:

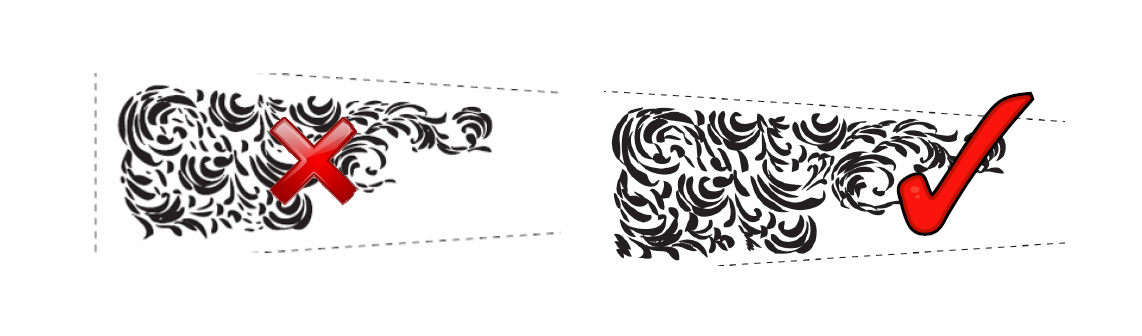

Correct: The TG pattern should be at least 1.5mm away from the edge.

Error: TG pattern is in edge position.

2. Cutting material: can not heat cutting material, need to use CNC carved temple shape.

3. Wire-core Shooting:

It is to reduce the temperature of the baking material when shooting wire-core as much as possible. The parameters for reference are as follows. Please adjust them according to the conditions of each factory:

- Use high frequency machines whenever possible;

- If using ordinary oven, the temperature must be controlled.

4. Repair temple shape and polishing

After shooting wire-core, the temple often has cracks at the TG position. Please repair the shape of the temple, but not tumbling, need to be polished. Examples of polishing effects:

# the eyewear factory reviews #Shenzhen eyewear factory # eyewear factory in china #high quality eyewear factory # china eyewear manufacturers # Chinese eyewear manufacturers # sunglasses manufacturers in china # china eyeglasses # oem eyewear manufacturers