1. Introduction to Decentered Lens Cutting

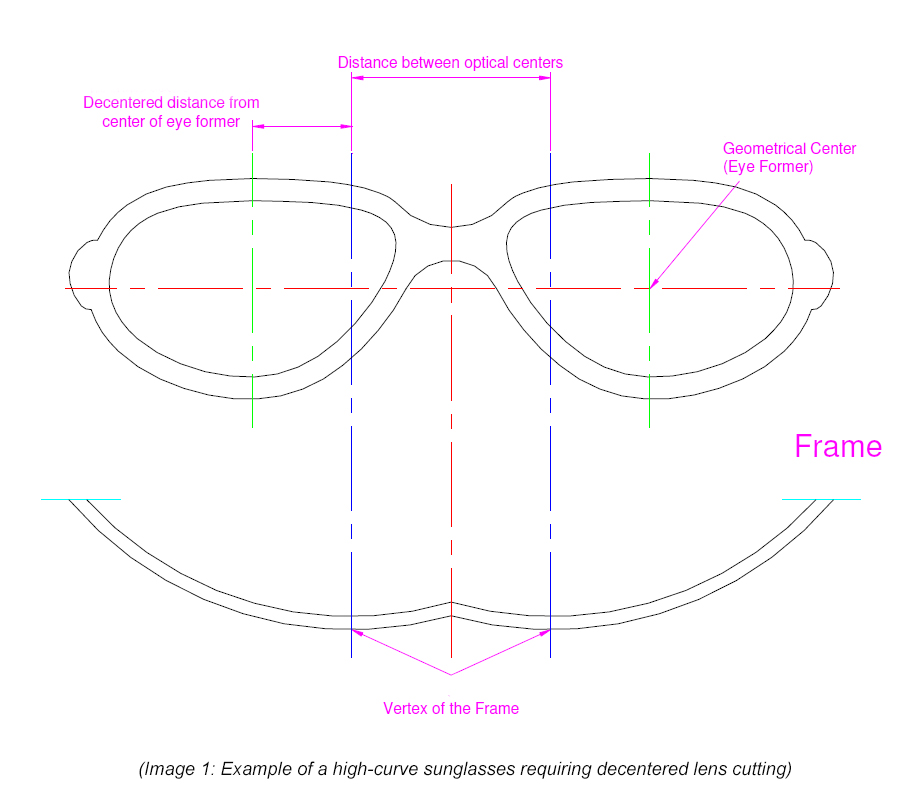

When manufacturing high-curve sunglasses at any reputable eyewear factory in China, proper decentration becomes crucial for lenses exceeding +8.00D. As noted in multiple eyewear factory reviews, the pronounced curvature of premium frames from Chinese eyewear manufacturers requires precise optical center adjustment to prevent wearer discomfort. This guide outlines the standard decentered cutting process used by leading China eyewear manufacturers, though machine-specific adjustments may apply.

2. Eye Former Standards

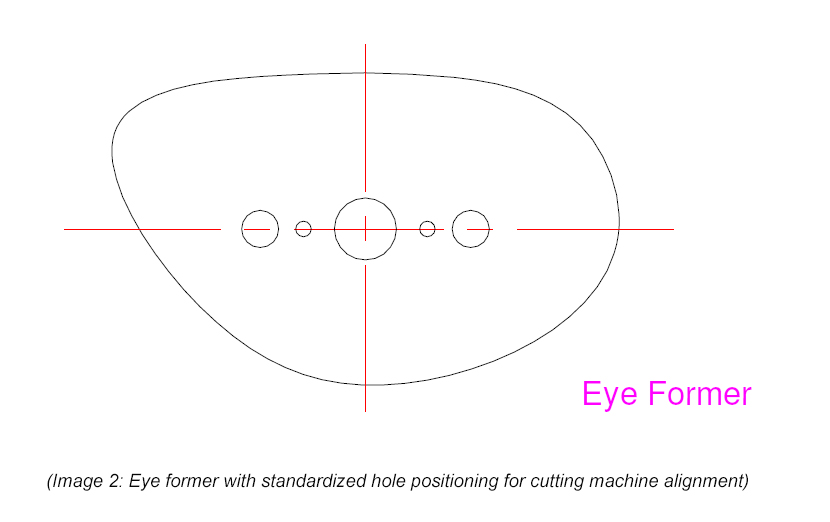

Top-tier China sunglasses manufacturers prepare eye formers according to strict ISO 12312 and ANSI Z80.5 standards. These specifications, rigorously followed by eyewear factory China operations, ensure proper hole positioning for cutting machine alignment. Deviation from these standards - a common issue in substandard facilities - can critically distort the optical center in decentered lens production.

3. Lens Preparation for Decentered Cutting

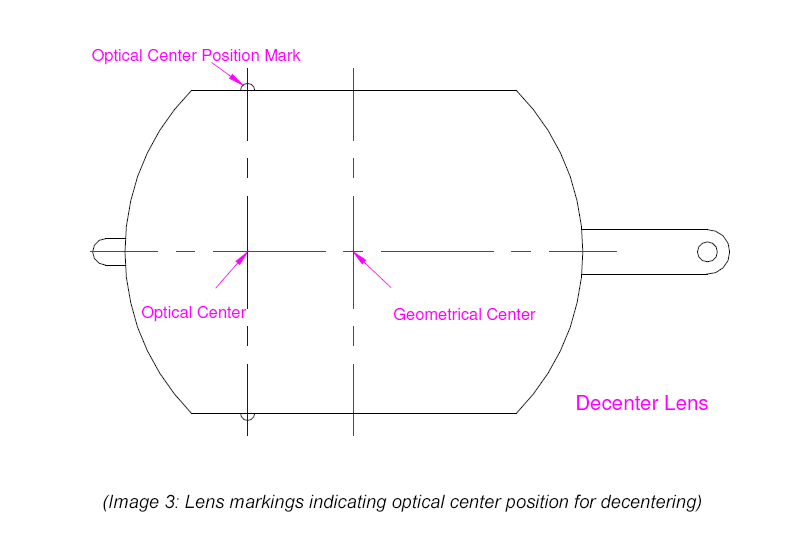

When sourcing from China eyewear factory direct suppliers, ensure lens blanks accommodate the decentered position's requirements. The optical center shift toward the bridge and upper frame significantly reduces usable lens area if not properly planned. As practiced by quality-focused Chinese eyewear manufacturers, always reference the two small marking pins on the lens edge that indicate optical center position during setup.

![]()

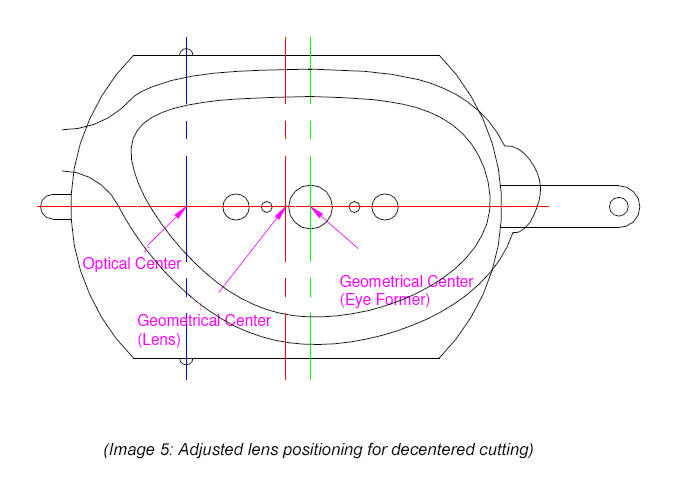

4. Alignment Principle for Decentered Lens Cutting

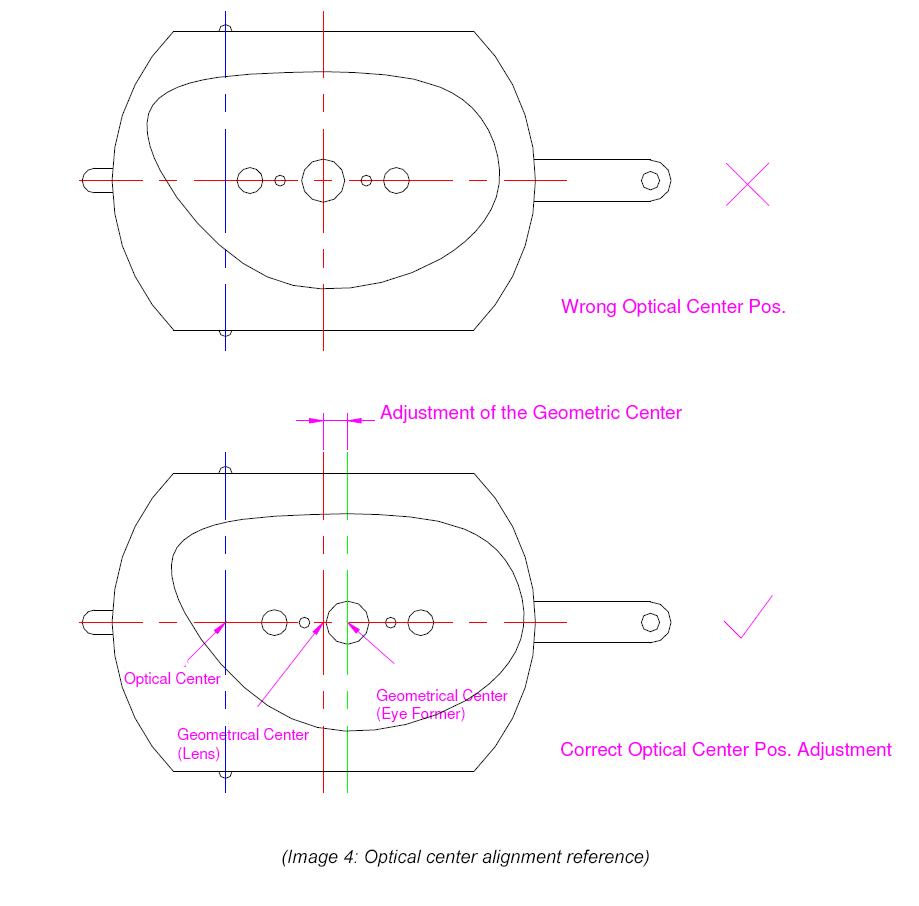

The hallmark of premium eyewear factory China production is perfect alignment between the lens's optical center and eye former geometric center. While standard cutting positions the lens at the segment center, decentered production - as perfected by leading China sunglasses manufacturers - requires calculated fixture adjustments to shift the rotation point appropriately.

· In Image 4, the optical center (green line) is determined based on the frame in Image 1.

· The distance between the green and red lines represents the required adjustment.

· Image 5 demonstrates the combined adjustment from Image 4 applied to the frame in Image 1.

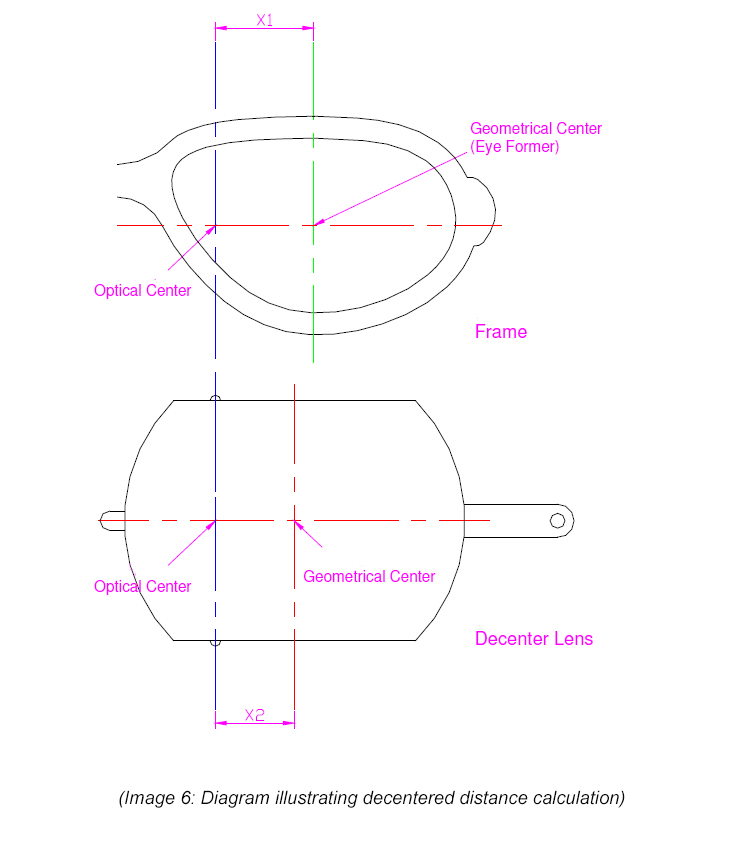

5. Calculating Lens Offset for Cutting Machines

Precision-focused China eyewear manufacturers follow this offset calculation:

· X1 = Eye former decentered distance

· X2 = Lens decentered distance

Offset = X1 - X2

(Positive result: shift toward optical center; Negative: shift away)

This method, frequently highlighted in eyewear factory reviews, ensures optimal lens positioning.

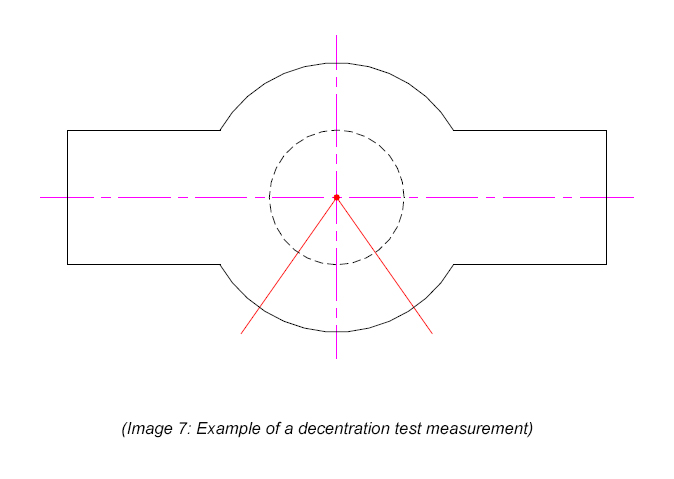

6. Post-Cutting Verification and Tolerance Control

Consistent with best practices at eyewear factory in China facilities, always conduct decentration tests after initial cuts. As China eyewear factory direct suppliers know, proper alignment verification prevents costly mass production errors. The tight tolerance control demonstrated by top Chinese eyewear manufacturers separates quality production from inferior operations.

#acetate eyewear #titanium eyewear #Shenzhen eyewear factory #lamination eyewear #China eyewear factory #custom sunglasses #high quality eyewear factory #wood eyewear #deans eyewear factory